About Artech

Artech is a specialist partner to hundreds of industries using Capacitor Discharge Welding technology. One of the few companies, globally, to develop the Capacitor Discharge Welding technology, Artech comes with proven capabilities to help small and large companies from various industries to take up Capacitor Discharge Welding.

Founded in 1994, Artech was one of the earliest machine tool manufacturers in India to do indigenous development of specialist Capacitor Discharge Welding. What started as a mission to serve the Indian industry’s need for access to specialist technology has taken roots globally.

Today, Artech’s machines are leading the way across several established as well as emerging industries to drive product innovations through better welding technology.

Why Artech?

- Long standing expertise of over 25 years in Capacitor Discharge Welding Technology

- Partner to hundreds of companies in enabling better welding, efficiently

- Fully indigenous technology developed by industry’s best R&D team

Capabilities

Design

- Dedicated R&D team with combined expertise of 60+ years

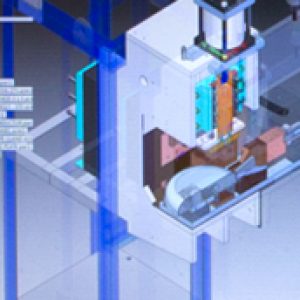

- Advanced 3D modelling for machine design, tooling and automation

- Compliance with international safety and design standards

Manufacturing

- 3 plants located strategically to serve local and global markets

- Team of 30+ Engineers and Technicians for production, assembly and quality

Applications

- Focused engineering team to help customers in developing and optimising technology for their application

- Evolved processes to prototype and scale up new applications using CD Welding technology

Service

- Team of expert engineers serving multiple locations

- Quick supply chain with stock of critical and standard components

- Mobile App for customers to register service calls