Beyond welding. Technology that improves your product.

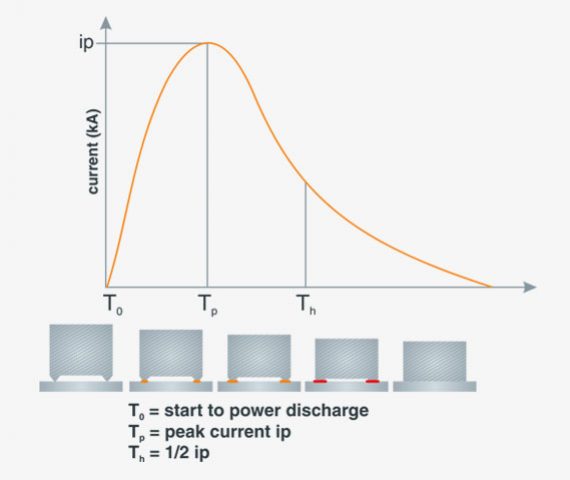

Capacitor Discharge Welding. Current up to 200,000 A. Weld time of less than 10 milliseconds. 70% lesser power requirement, compared to conventional projection welding, remains the most important advantage of Capacitor Discharge welding.

Capacitor Discharge (CD) Projection Welding

In CD Projection Welding the weld area and location is pre-defined by giving a small projection (1 to 4 mm) on one of the weld components. During welding, the projection collapses under the electrode pressure and very high current passing through the electrodes fuses, the metal fuses to create the join. With weld time of less than 10 milliseconds and focused discharge of weld energy,

the heat does not conduct beyond welding area leaving the welded parts clean and distortion free.

The CD Projection welding can be performed on a multiple projections, simultaneously. The work-pieces are pressed at the projection using pneumatic/hydraulic or servo motor drives.

Advantages

- The best in aesthetics No black marks, spots or distortions. Just clean and beautiful welds.

- Significantly lower Kva Up to 70% savings in power, forevery weld that you do.

- Totally leak proof welds Trusted for leak-proof for most critical applications

- Freedom from post weld processes & costs Save time and costs with no need for post weld processes, whatsoever.

- Requires no water cooling With no heating of electrodes, the need for water cooling is eliminated reducing costs of electrode and fixture maintenance.

- Run it on Genset. Yes! Lesser demand for input power means machine can run on 3-phase power supply.

- Weld heat sensitive parts Minimal heating and lowest welding time enables welding of heat sensitive parts with ease.

- Weld dissimilar surfaces Strong, clean joins even for all surfaces similar or dissimilar

- Lower day-to-day running cost Lowest operating costs with minimal maintenance and significantly lower power consumption

Technical Specialties

- Consistent current delivery

- Heating and fusion only at the actual welding area

- Delivers current up to 200,000 A

- No effect on welding quality due to normal voltage fluctuations

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component