Diamond Segment Welding

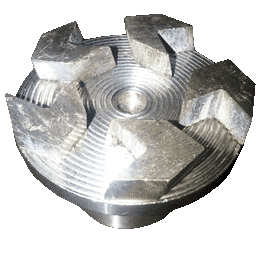

Artech’s Capacitor Discharge Welding technology is being adopted as an cost-effective option to relatively costlier laser welding that is prevalent in the market today.

Diamond Segment Welding

Diamond Segment Welding

Diamond Segment Welding

Diamond Segment Welding

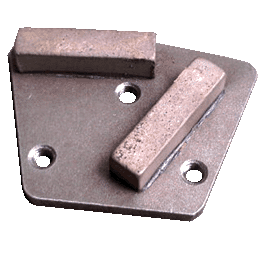

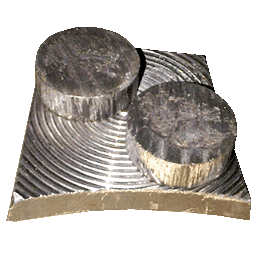

Artech offers advanced and automated Capacitor Discharge Welding machines for diamond segment welding of cup wheel and core drill. The machines, designed specially to suit the diamond segment, ensure fast, efficient, and quality welding for the products.

With welding strength equivalent to all other alternatives, and far lesser running costs, manufacturers are choosing Capacitor Discharge welding, over other options such as laser welding. Artech’s machines are used by industry leaders in both India as well as overseas markets.

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component