Drawn Arc Stud Welding

Drawn arc stud welding is a highly efficient method of attaching fasteners primarily to mild steel and stainless steel by utilizing a constant current DC power supply. The process uses a welding rectifier which serves as an energy source and provides continuous welding current. The welding time can be adjusted from 10 to 600 milliseconds.

Process

During welding current begins to flow through the stud while the weld gun simultaneously lifts the stud to draw an arc that melts the base of the stud and adjoining workpiece surface. Upon completion of the weld time, the gun plunges the stud back to the workpiece, resulting in a permanent bond as molten material solidifies under concentrated welding arc induced by ceramic ferrule around stud base.

Advantages

- Excellent reliability and uniform quality

- Requires no flux or filler

- High duty cycle

- Eliminates need fo drilling and riveting

Features

- Password protection

- Alpha-numeric text display

- Fine adjustment of weld time and weld counter

- Protection against overloading of machine

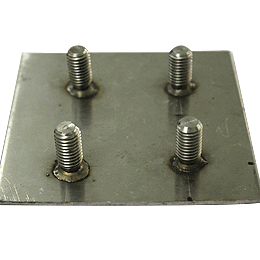

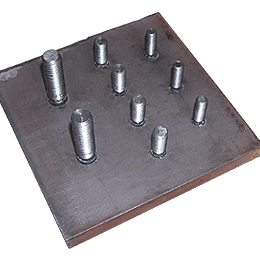

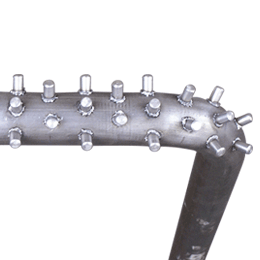

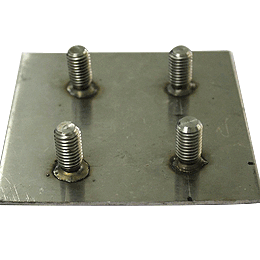

Work Gallery