Leak Proof Welding for a variety of applications

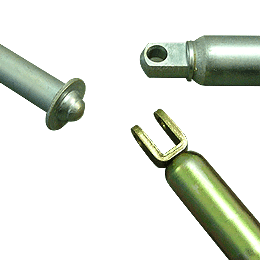

Automotive Shock Absorber

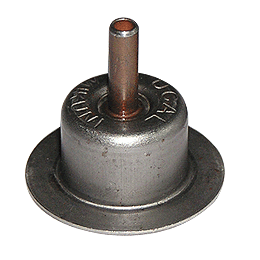

Leak-proof welding in semiconductors

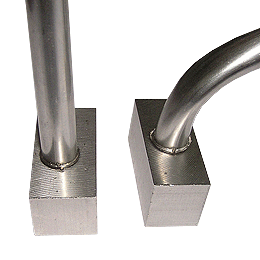

Leak-proof welding for pipes

Leak-proof welding in pipes

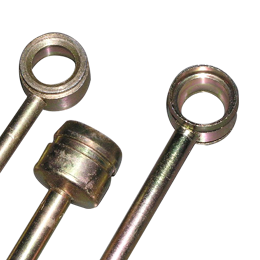

From safety components in automotive shock absorbs to valves in pressure cookers, Artech’s Capacitor Discharge Projection Welding machines are key to ensuring strong and clean leak proof welds for a variety of components.

Why Artech

Artech’s CD Welding technology easily helps achieve leak proof welds owning to deformation free welding process. Significantly lower power consumption, strong weld joins and clean welds are additional advantages.

Leak-proof welding of pipe to plate

Stabilizer Bar Welding

Artech’s CD Welding technology easily helps achieve leak-proof welds owning to deformation-free welding process. Significantly lower power consumption, strong joins done by Projection welders, and clean welds are additional advantages.

Further, Artech designs innovative fixtures for its machines to perform single or multiple welds as per your requirement. Some of world’s largest companies trust Artech as their singular source to perform leak proof welds for their critical safety components.

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component