Service

Service Advantages

Startup

Operator training.

Support production staff to monitor quality.

Maintenance

Quick support to resolve critical issues.

Routine preventive maintenance.

Productivity

Expert support for productivity enhancements.

Machine/process/component configuration for optimum productivity.

Refurbishments

Repair and refurbish support for your old machines

Spares

Dedicated team for spares support.

Assured availability of spares at lowest price.

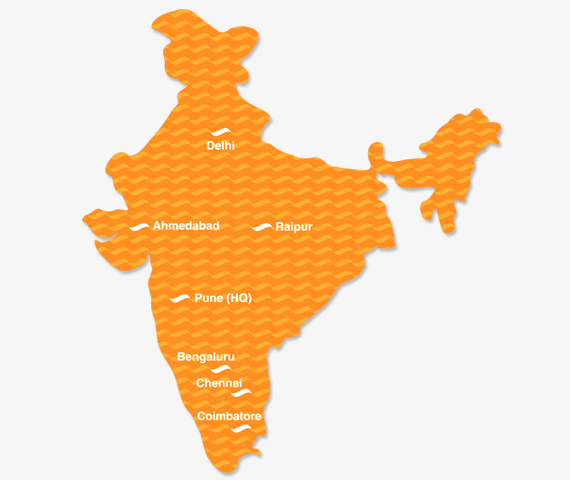

Nationwide Support

Instant Service App

Artech’s Machines now feature an instant service Mobile App which enables anyone to register service calls, instantly. The App is available for free download on Andriod phones and all one needs to do to register service call is to scan a unique QR code available on Artech’s Machine. The App intimates Artech’s service team and keeps a track of progress till successful closure of issue. Customers can also access O&M Manual, Machine maintenance history through App.

Need help to shift to better welding?

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component