Superior Welding for Automotive Components

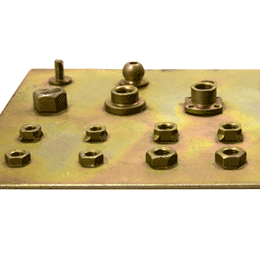

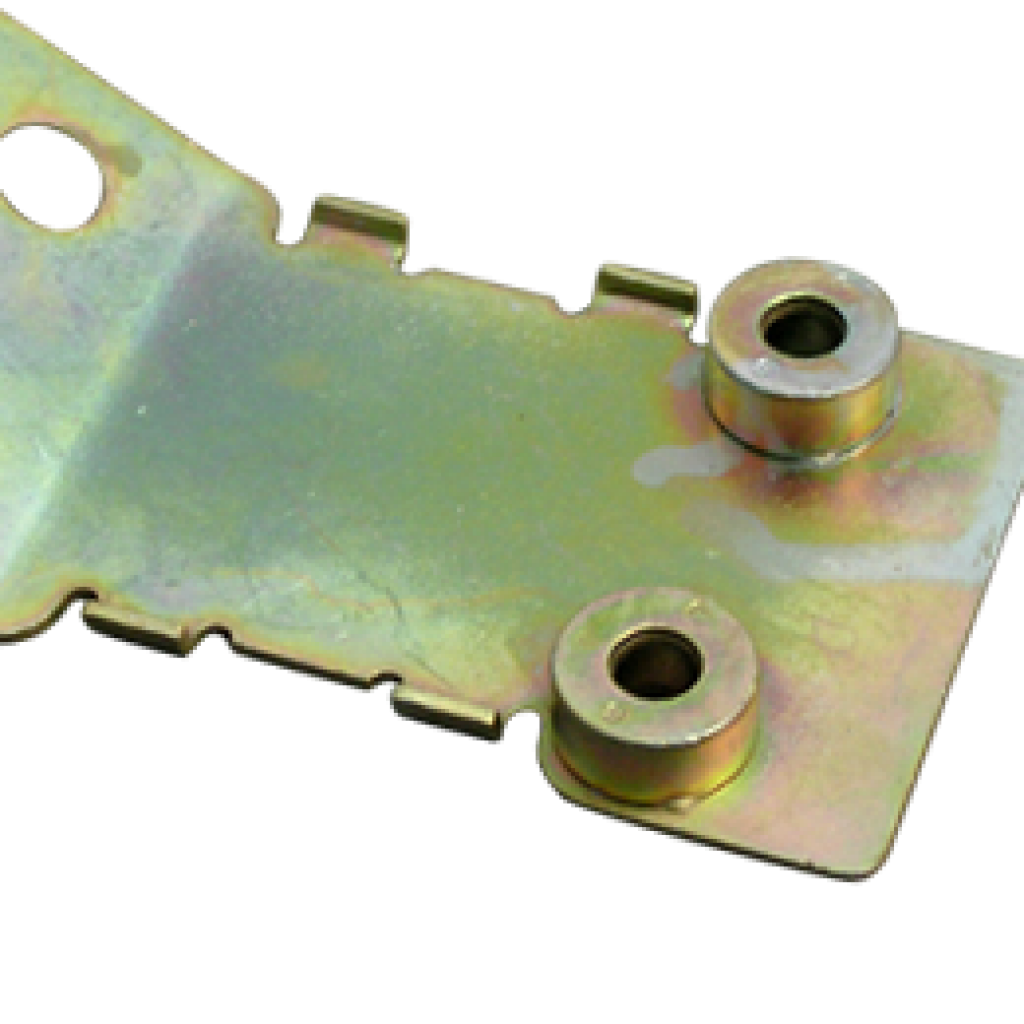

Nut Welding

Knuckle Bracket Welding

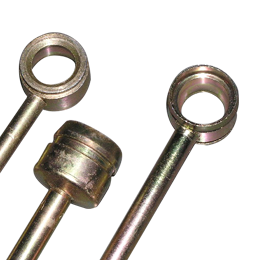

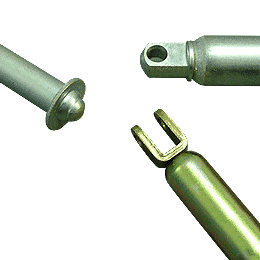

Yole to pole welding

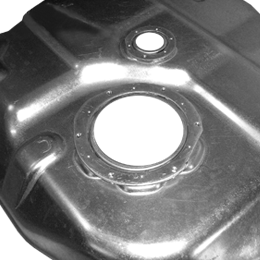

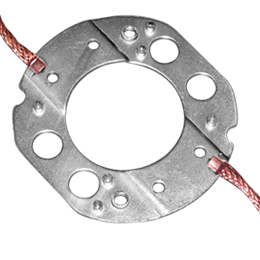

Fuel Tank Ring Welding

Latest Development

Artech’s CD Welding technology serves a large variety of applications in the automotive industry, starting from simple nut welding to auto-electrical components. Since founding, Artech has been working with top automotive manufacturers in their quest to shift for better, cost-effective and productive welding.

Why Artech

With hundreds of installations & some of the world’s largest automotive manufacturers as its clients, Artech’s Capacitor Discharge Welding technology has set a quality benchmark in common applications as well as specialised areas. Significant cost savings in day to day power consumption, superior finish, highest reliability of Artech’s Capacitor Discharge Welding Machines.

Welding for Window Regulator

Oil Filter Top Plate Welding

Welding for Sintered Components

Stabilizer Bar Welding

Yoke to Pole Welding Machine

Equipped with Poka-yoke

– Current monitoring

– Set-down monitor

– Force change

– Part presence sensors

– Rejection bins

– Live data feed

Nut Welding

Round Nut Welding

Shock Absorber Component Welding

Welding of Braided Copper Wire

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component

News & Events

Long before Make in India became a headline, it was already a way of working. The journey began

Up to 24 joins in a single stroke for Pump Impellers Artech’s Capacitor Discharge welding machines have been

Up to 80% Power Savings in welding With conventional welding the three components, to be joined simultaneously, in