Capacitor Discharge Stud Welding Machines

Artech offers CD Stud Welding machines that are suitable to join small diameter studs to thin base metals. Capacitor Discharge Stud welding cycle is completed in 2-3 milliseconds on material as thin as 0.02 inch. The small weld times minimizes the amount of heat generated and penetration depth into the parent material making it ideal for welding smaller diameter ferrous non-ferrous studs on thin gauge base metals.

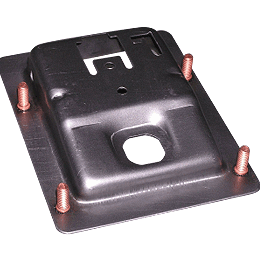

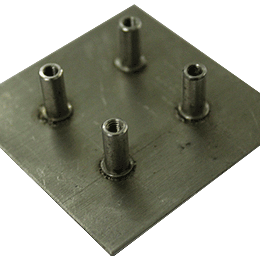

The stud or fastener can be welded on the reverse side of the coated or finished sheet with very little or no discoloration, distortion or burning. Stud welding provides a high-quality joint that is strong and resists loosening or breaking.

Process

Advantages

- Uniform high Welding Quality

- Requires no re-working on the other side of weld

- Requires no additional material such as flux, insert gas

- Elimination of other operations like drilling, riveting etc

- No leakages even when welding on containers

Features

- Password protection

- Display and keyboard to set & save parameters

- Weld counter

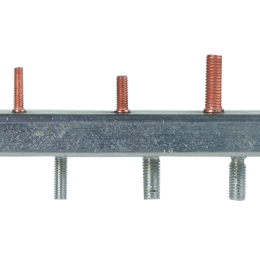

Work Gallery

News & Events

Long before Make in India became a headline, it was already a way of working. The journey began

Up to 24 joins in a single stroke for Pump Impellers Artech’s Capacitor Discharge welding machines have been

Up to 80% Power Savings in welding With conventional welding the three components, to be joined simultaneously, in