Welding in Hollow Metal Doors

Welding of Door Frame Brackets

Extensive Range

Extensive Range

Extensive Range

From delivering the first machine for welding application in hollow metal door in 2008 Artech has served almost every leading manufacturer, including some of the world’s top brands. Artech’s CD Projection welding is especially recognized to deliver multiple clean welds, in a single shot. With 50+ installations across India and other key markets across the world, Artech’s CD Projection welding Machines are an undisputed leader in the category.

Why Artech

Delivering excellent aesthetics, superior weld strength and greater productivity, Artech’s CD Projection welding technology is at the heart of quality of hollow metal doors. Industry leading manufacturers rely on Artech’s machines to manufacture their entire range of doors.

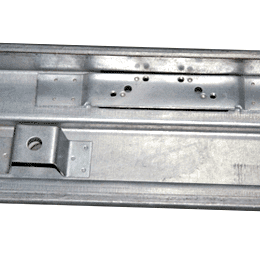

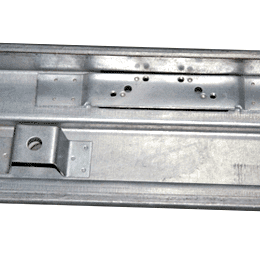

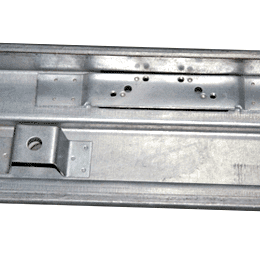

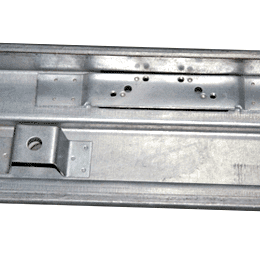

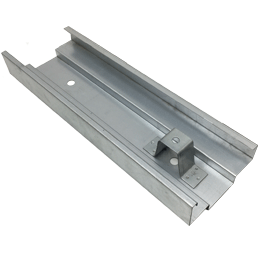

C-Channel Welding

Welding of internal component

From clean room applications, commercial, industrial, and special applications to fire safe hollow metal doors, customers using Artech’s CD projection welding technology have found it to exceed the standards in every domain. The Machines are used by several international manufacturers, and weld quality certified by leading industry bodies and local regulatory agencies.

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component

News & Events

Long before Make in India became a headline, it was already a way of working. The journey began

Up to 24 joins in a single stroke for Pump Impellers Artech’s Capacitor Discharge welding machines have been

Up to 80% Power Savings in welding With conventional welding the three components, to be joined simultaneously, in