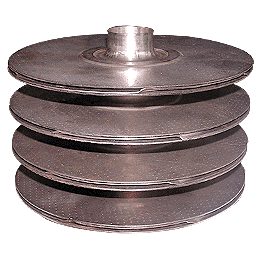

Welding for Pumps and Impellers

Multiple Welds for Impellers

24 Welds in a single stroke

Impeller Welding for intricate shape

Superior welding for high performance impellers

Artech’s Capacitor Discharge Welding technology has been leading the way, in the shift from Cast Impellers to Sheet Metal Impellers for Pump Manufacturers in India, since early 2000. With greater productivity and better aesthetics for sheet metal impellers, Artech’s CD Projection welding has been key to the growth of pump industry in both domestic as well as export markets. Leading pump manufacturers rely on Artech’s technology to perform welding on impellers and related components.

Why Artech

With over 60+ installations, and presence across every pump manufacturing cluster in India, Artech’s application engineering expertise has been pivotal in driving the pump industry’s shift from cast impellers to sheet metal impellers. Offering excellent aesthetics and multiple welds in one stroke, Artech’s CD Projection welding machines have set a new benchmark in quality and productivity of impellers.

Clean finish and aesthetics for Impellers

Superior welding for impellers

Starting from optimising impeller designs for better welding to designing intelligent fixtures for faster production, Artech’s application engineering team has an extensive know-how of leveraging the strengths of Capacitor Discharge projection welding machine in manufacturing impellers. Over 75% repeat business and decades of relationship with customers is a testimony to Artech’s success in the pump industry.

Need help to shift to better welding?

Starting from assessing suitability of projection welding to proving the component with your end customers, Artech’s Application Engineering team will help you at every step.

Get in touch with us, now!

- Free trials to prove your welded components

- Select the best Machine design & related automation

- Test and prove the welded component

News & Events

Up to 24 joins in a single stroke for Pump Impellers Artech’s Capacitor Discharge welding machines have been

Up to 80% Power Savings in welding With conventional welding the three components, to be joined simultaneously, in

Safe, efficient and consistent joins for Knuckle bracket Kuckle bracket is a safety critical component. The manufacturing involves