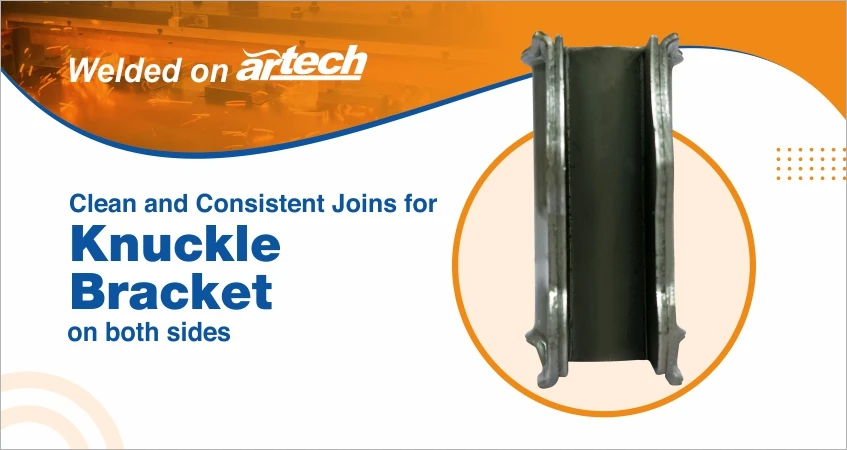

Safe, efficient and consistent joins for Knuckle bracket

Kuckle bracket is a safety critical component. The manufacturing involves performing multiple welds on a relatively complex profile. Conventional welding demanded very high power (200 KVA) which in turn had its own challenges in terms of heating of components and longer set down time. Further, being a safety-critical component, the client wanted to eliminate every risk by monitoring of weld quality for each component.

Artech’s Capacitor Discharge Projection Welding technology solved all these challenges in one go. With Artech’s 30 KVA Capacitor Discharge Welding Machine, the client was able to perform clean, distortion free welds. Artech also designed a machine that could weld on both sides of the knuckle bracket simultaneously, saving time and reassuring quality for the component.

Benefits

- Up to 70% savings in power

- Consistent quality with weld current monitoring

- Higher productivity with no post weld processes, welding in a single stroke