Projection Welding is a popular type of resistance welding. As the name suggests, Projection Welding is used for welding multiple projections on the workpiece. I. . These projections can be circular, round dimples, extended corners, rib type, or elongated ridges of weld nuts. Let’s dive deeper into the Projection Welding Process to understand it better.

Working Principle of Projection Welding

- Copper electrodes are used in projection welding as copper is a good conductor of electricity and heat.

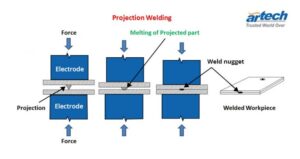

- The two metal workpieces to be joined are placed between the two electrodes. These electrodes are kept upwards & downwards as shown in the figure above.

- External Pressure (force) has a huge role to play in this welding.

- A large amount of force is applied to the electrodes. This force eventually gets transferred to the workpieces.

- After that, the current is passed through the electrodes. As the current passes, it generates heat due to the internal resistance of the metal workpieces.

- Now, the produced heat due to resistance is concentrated at the projections on the workpiece as the two workpieces are placed in a manner that the metal sheets come in touch only at the projection points.

- Projection Welding Workpieces have fixed, predetermined projections. All of them get welded in one shot.

- Due to the applied pressure on the workpiece, the projections collapse and get fused. Weld nuggets are formed at the projection spots.

- Finally, a quality weld is formed and the two metal workpieces are welded successfully!

Key Advantages Of Capacitor Discharge Projection Welding

The most significant advantage of this welding is the ability to weld more than one spot in a single stroke. You can expect clean weld joints due to less weld time. This process of Projection Welding consumes less power Hence, it is a good option for usage in manufacturing units. It is also known for longer electrode life as there is minimum heating.. When compared with Spot Welding, Projection Welding has more minor limitations.This type of welding also maintains excellent heat balance during the welding process. Another big advantage, the process of projection welding is suitable for automation.

Welding With Artech Machines!

Artech is known for an unparalleled set of capabilities in Welding Technology. Today, our welding machines are trusted by well-established as well as growing industries to drive innovation in their manufacturing products through cutting-edge welding technology. Artech has a dedicated R&D team with combined 60+ years of expertise. We understand the changing needs of industries and bring welding machines that can help better in manufacturing. With the help of Advanced 3D modelling for machine design, tooling and automation technology, Artech is the name you can trust! Connect to our team and discuss your welding machine requirements. From Capacitor Discharge Projection Welding to Stud Welding and more, your search for perfect welding machines ends at Artech!

Shift to better welding with us!